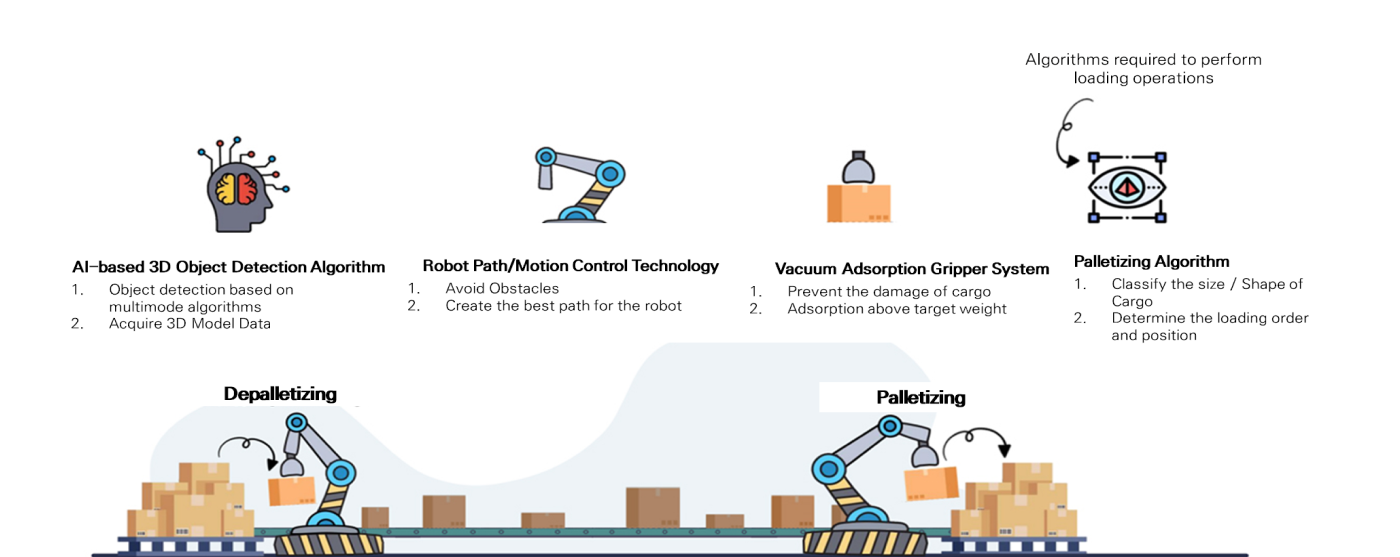

Smart logistics system is on-site automation by controlling and managing/operating all activities of logistics sites in real time by combining various IT technologies (artificial intelligence, information communication technology, sensor and control technology, etc.) and services in existing logistics centers. It is a system that aims to improve efficiency and sustainability in logistics operations and reduce logistics costs through construction and unmanned facilities.

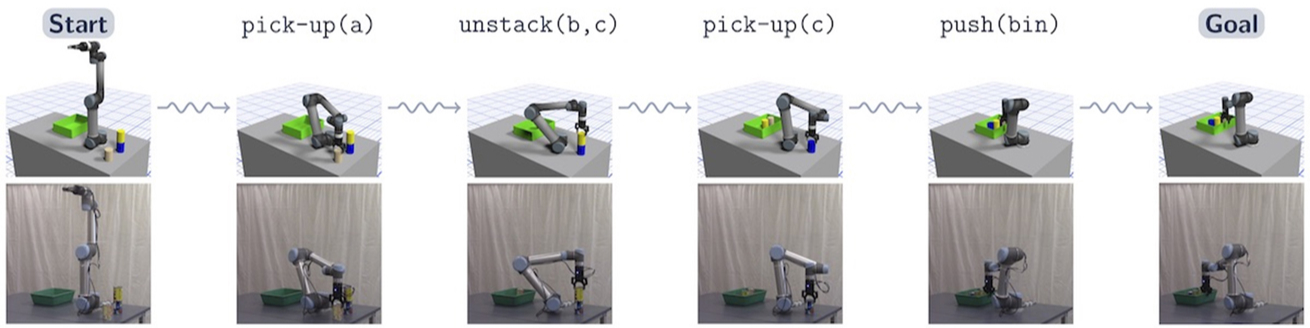

AI-based smart logistics robot that gives robots vision and intelligence (AI) to enable logistics tasks instead of humans.

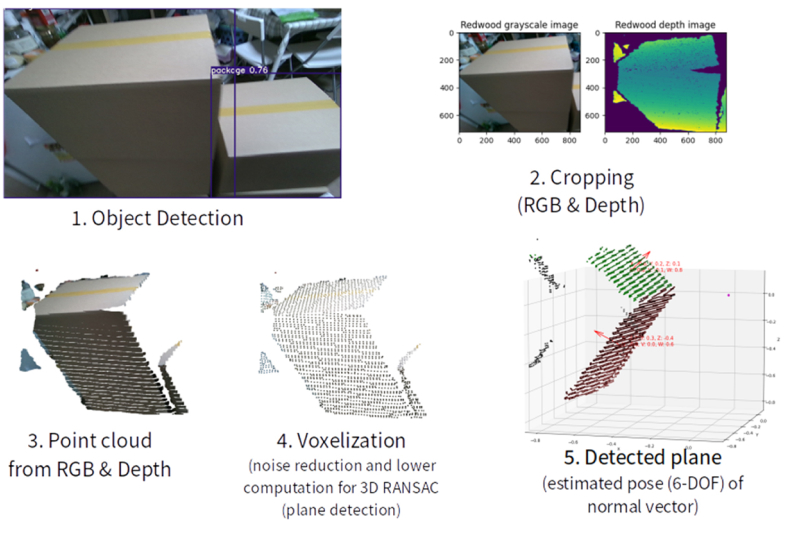

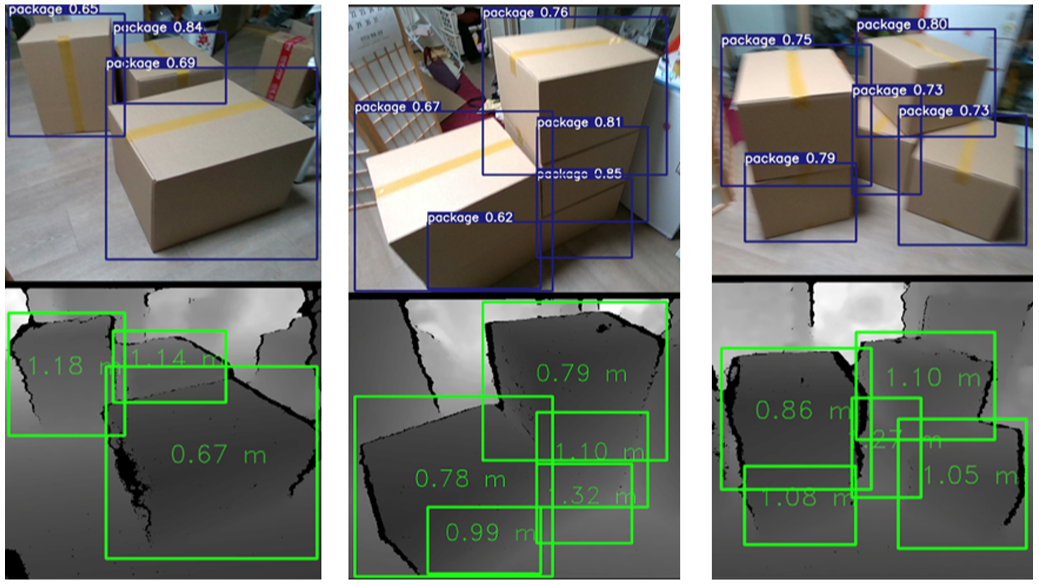

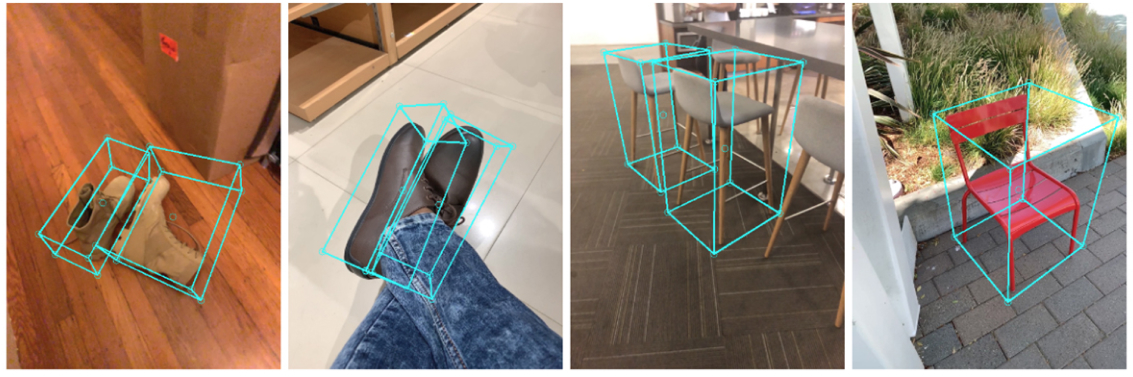

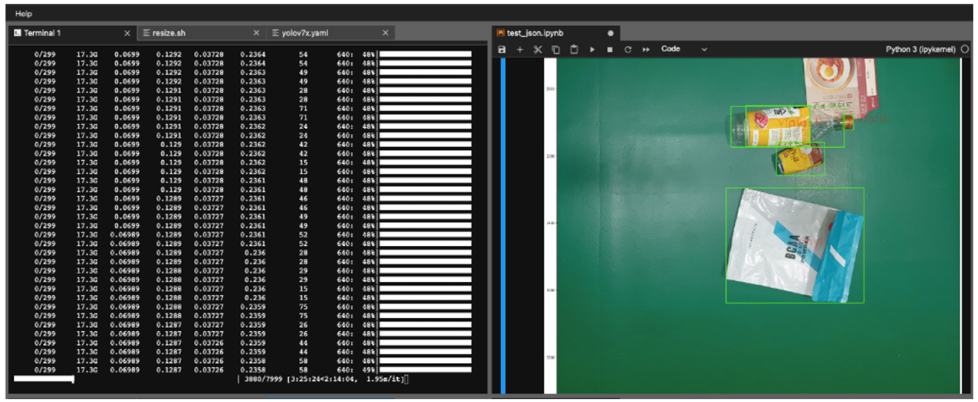

AI-based 3D object detection algorithm

Smart detection algorithm that can detect objects of different shapes, sizes, randomly placed objects, and even if the image is shaken

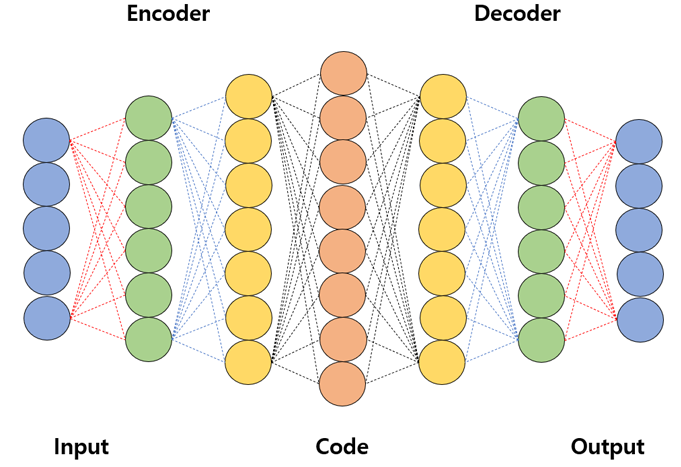

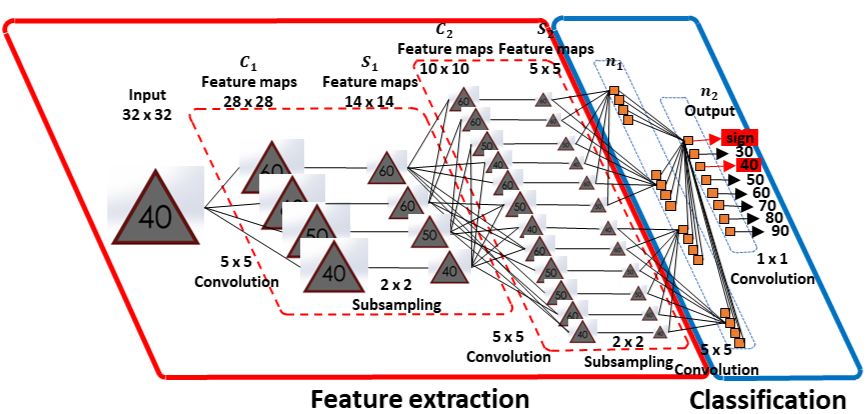

Extraction of visual features required for object detection in images through AI models such as Autoencoder, CNN etc.

Encodes the input image to a lower dimension than the input dimension, decodes it again, and outputs an image close to the input image

Extract important features using a CNN model trained on a large amount of image data

Extract the geometric features required for object detection from the point cloud

Improved and utilized AI models that fit geometric features. Extract geometric features by modifying/improving AI models such as FCAF3D and STRL designed in consideration of the point cloud characteristics

AI model that extracts multimodal features by combining/selecting the extracted visual and geometric features, and finally detects the box

3D bounding box and classification result for the detected object are output

Improving detection ability through continuous AI training

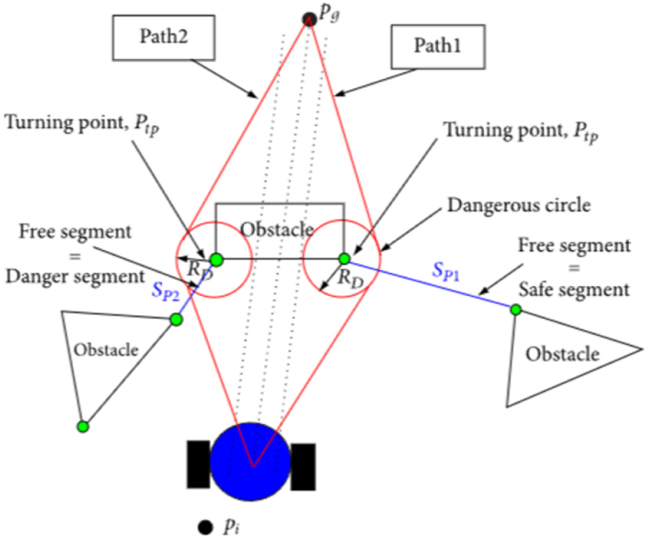

Robot path/motion control technology

Reduce noise and point cloud computations using RANdom SAMmple Consensus (RANSAC) model

Set reference coordinate system between RGB camera and lidar/ToF camera in 3D vision